module-contentPrototypes in serial production quality

Plastic parts in smallest lot sizes (3D printing, milling, thermoforming and vacuum casting)

module-contentLot size 1 to…

Whether it is sample versions, functional models or already the first small series in serial production quality, Hombach provide the correct technology (e.g. 3D printing, thermoforming, vacuum casting, 5-CNC milled parts) for a fast and high quality implementation.

module-content

Project-specific implementation

Project-specific requirements tailored to customer needs are considered. The components produced in this way not only enable a first impression in original size, but can also be used as functional and interfering contour tests, or even as pre-series parts, to enable a fast market launch for example.

module-contentState-of-the-art machinery and finishing options

There is no limit to the quality and size due to our state-of-the-art machinery and the in-house further processing and surface finishing processes.

Our technologies enable prototypes in one piece of up to 3000 mm x 2500 mm. If required, even larger multi-piece models can be set up (i.e. for transport reasons).

module-contentSeries quality from the first component

State-of-the-art production technologies and the use of series-identical material facilitate high-quality prototypes and small series from the smallest lot sizes of 1.

This means that even small series can be realised without investment in tools. With our professional further processing and surface finishing, no difference to the subsequent serial component can be detected.

module-contentHigh material diversity

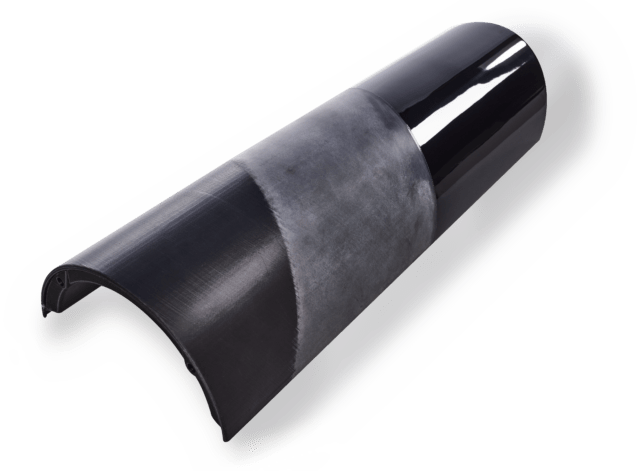

Depending on the area of application, the prototypes consist of high-quality and even series-identical materials. In addition to standard thermoplastics such as ABS, ABS-PC, PC, PET-G and PP, high-performance plastics like PEI, PEAK, PEEK can also be used.

Furthermore, special types are possible, which comply with the fire protection standard of the UL 94 V-0 for example, or with the EN45545 HL2 R1 common in rail transport. What’s more, flexible plastics such as thermoplastic polyurethanes (TPUs) or carbon fibre-filled polyamides (PA-CF) are feasible.

Polyurethane and other cast resin systems are used for large-scale milled parts and vacuum cast parts.

module-contentPlease present us with a challenge, we look forward to your project.

Decades of experience in working with plastics combined with the highest standards of quality and a passion for creating unique products for our customers are our hallmark. Clear and open communication about the possibilities is a matter of course for us. We look forward to your challenges!